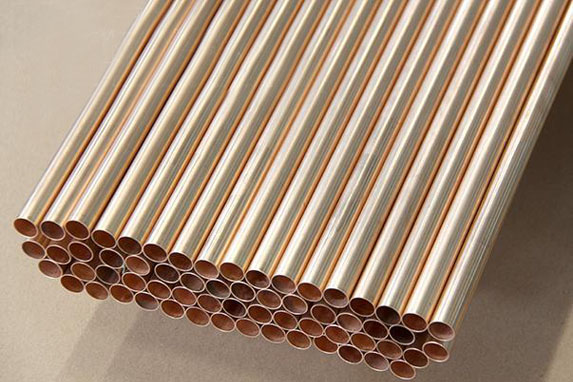

- RockySea Petro is precision rolling pipe has extremely high precision and straightness can be less than 0.01mm/m.

- RockySea Petro manufactures a variety of precision rolling pipe, such as low carbon steel, stainless steel, brass, bronze, etc

- RockySea Petro is GE, SCHLUMBERGER, DOVER excellent supplier.

- RockySea Petro has 20 years of Precision Rolling Pipe experience.

- RockySea Petro is the best Precision Rolling Pipe Manufacturers for Precision Rolling Pipe wholesale.

RockySea Petro Precision Rolling Pipe

The RockySea Petro precision rolling pipe can be used for downhole pump barrel & plunger, sucker rod coupling, ESP housing, motor bearing, and housing.

In 2015, RockySea Petro established precision rolling pipe production line.

The quality and accuracy are at the leading level in China.

The annual production capacity reaches 4000 tons. RockySea Petro Petro is GE, SCHLUMBERGER, DOVER excellent supplier.

Precision Rolling Pump Barrel

Precision Rolling Pump Barrel

When it comes to barrel type, these pumps can be categorized as heavy-wall, thin-wall, and heavy-wall with thin-wall thread configuration. This is discussed below:

Heavy-wall

These are pumps with wall tubing that measure between 0.393 and 0.472 inches.

They are threaded externally, which allows the plunger to stroke out at both sides of the pump.

This stroke-through construction created in the process prevents the formation of scale inside the pump barrel.

Heavy-walled barrels are stronger and more rigid to ensure greater setting depth. Additionally, they come in two types; with a metal plunger (H) and a soft-packed plunger (P).

Thin-wall

This is a type of pump with wall tubing measuring between 0.197 and 0.276 inches.

They are threaded internally and have the most massive bore relative to any given tubing size. Accordingly, these pumps are suitable for moderate wellbore depth and come in two categories: a metal plunger (W) and a soft-pack plunger (S).

Thick – wall and thin – wall pumps barrel are honed to complete the final process.

But when the materials are special, such as stainless steel or brass, or the cylinder diameter is too large, the honing process cannot meet the accuracy requirements of the barrel.

At this time, the Precision rolling process can only be used for the manufacture of the pump barrel.

Precision Rolling Pump Barrel

Precision Rolling Pump Barrel

When it comes to barrel type, these pumps can be categorized as heavy-wall, thin-wall, and heavy-wall with thin-wall thread configuration. This is discussed below:

Heavy-wall

These are pumps with wall tubing that measure between 0.393 and 0.472 inches.

They are threaded externally, which allows the plunger to stroke out at both sides of the pump.

This stroke-through construction created in the process prevents the formation of scale inside the pump barrel.

Heavy-walled barrels are stronger and more rigid to ensure greater setting depth. Additionally, they come in two types; with a metal plunger (H) and a soft-packed plunger (P).

Thin-wall

This is a type of pump with wall tubing measuring between 0.197 and 0.276 inches.

They are threaded internally and have the most massive bore relative to any given tubing size. Accordingly, these pumps are suitable for moderate wellbore depth and come in two categories: a metal plunger (W) and a soft-pack plunger (S).

Thick – wall and thin – wall pumps barrel are honed to complete the final process.

But when the materials are special, such as stainless steel or brass, or the cylinder diameter is too large, the honing process cannot meet the accuracy requirements of the barrel.

At this time, the Precision rolling process can only be used for the manufacture of the pump barrel.

Precision Rolling ESP Housing

Precision Rolling ESP Housing

The ESP housing is a deep-hole thin-wall part with a shell length of 7m, the outer diameter of 98.5mm- 101.6mm, and the wall thickness of 4.75mm-6.4mm.

The straightness, coaxiality, wall thickness deviation, and surface roughness of the ESP housing have extremely high requirements and are difficult to manufacture.

During normal ESP operation, a good concentric rotation of the vane wheel and housing is required, which requires extremely high precision and quality of the housing.

The processing process of the ESP housing includes lathe processing, straightening, boring, rolling, and other links, which is complicated and difficult to process.

ESP housing and spline bearing made by RockySea Petro have high dimensional accuracy, which can be used directly without honing.